With MGT’s table mounted diamond roll changeover unit, decrease job set up time and gain valuable production time.

Improve Overall Equipment Efficiency (OEE) with MGT’s Quick-Change Diamond Roll Dresser Unit on your CNC grinding machine.

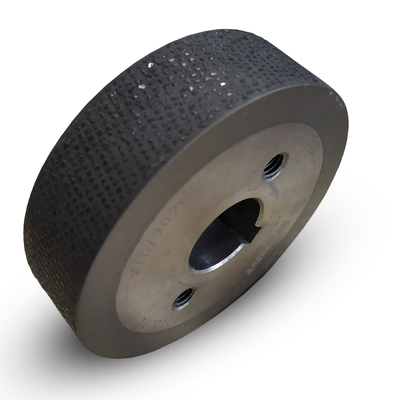

Once the sharp edges of the grinding wheel cutting surface are worn-out, they need to be restored by ‘Dressing’ the grinding wheel. Surface dressing tools such as Stationary Dressers and Rotary Dressers are commonly used for this process. While the cost of Stationary Dressers is lower, Rotary Dressers ensure form accuracy and do the job faster, thereby ensuring more machine up-time for productive work. Also, Rotary dressers typically last for months together whereas stationary dressers last only for a few days. Apart from these two types of dressers a much advanced and better dresser, the ‘Diamond Roll Dresser’, is being adopted for some time now. This helps to achieve not only consistent component quality but also improve OEE considerably. It is essential to use these dressers while working on components with critical profiles.

Stationary (Single Point) |

Stationary (Blade/Multi-Point) |

Rotary (Disc Type) |

Rotary (Standard Cylindrical/Roller Type) |

Diamond Roll Dresser |

Advantages of using Diamond Roll Dressers

- Increased dressing efficiency

- Improved grinding wheel life

- Desired profile can be achieved on the component in one-go

- Increases machine up-time as frequent replacement is not required

- Improve OEE due to accuracy & consistency of ground components

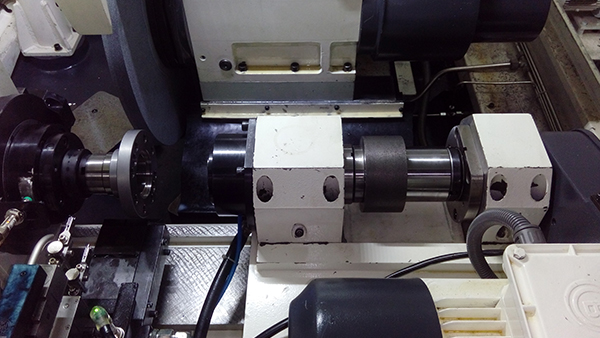

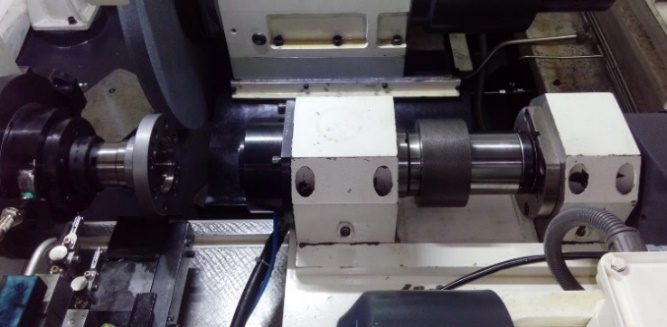

We at MGT have further explored means by which a machine’s OEE can be even bettered. Introducing the ‘Table Mounted Diamond Roll Assembly’ with Quick changeover feature.

|

- With the diamond roll fitted on an interchangeable mandrel, and by

- Enhancing the table mounted diamond roll attachment to provide for quick-change capability in case your production-run requires a different diamond roll for a component with another profile

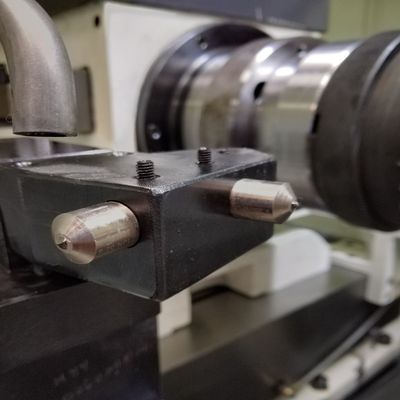

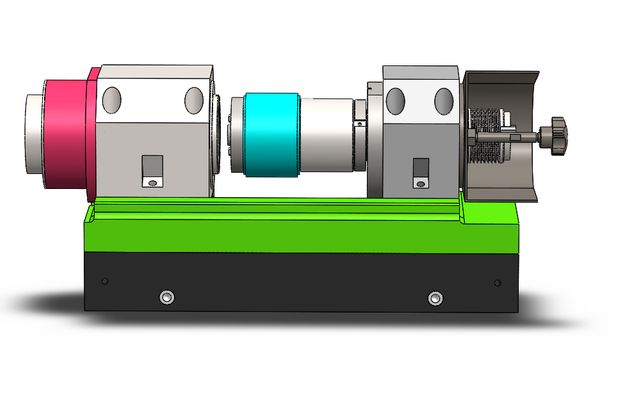

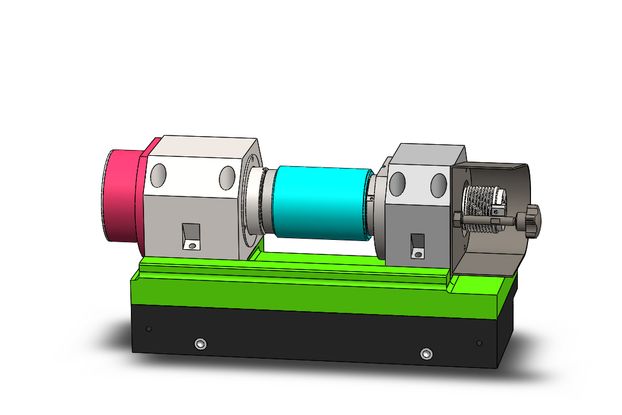

Step1: Quill moves forward and backward to enable the Diamond roll removal

|

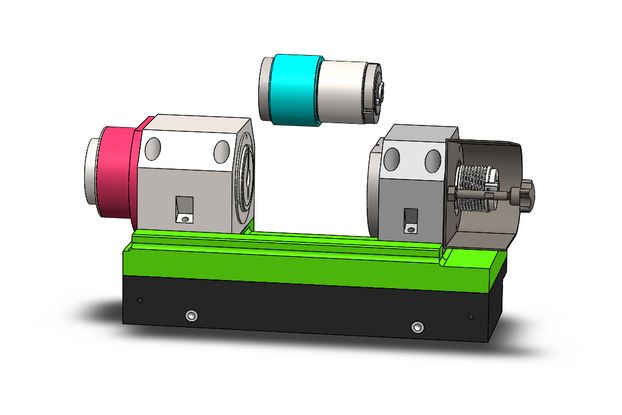

Step2: The first diamond roll being removed

|

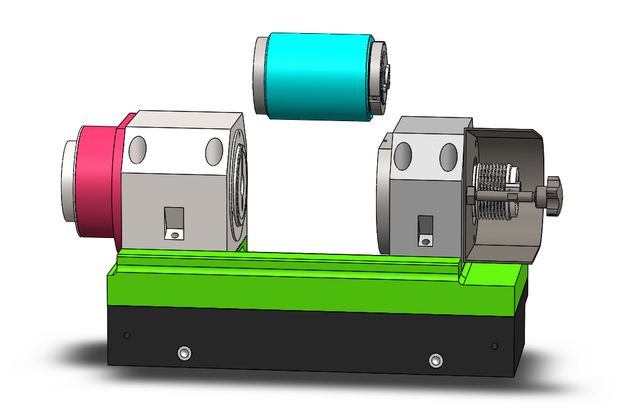

Step3: Second diamond roll being mounted

|

Step4: New diamond roll in place

|

This 4 step quick-change capability ensures faster and more efficient operations for working on components with different profiles in each production-run.

We at MGT, are now building approximately 25% of the CNC grinding machines with the provision of Diamond Roll Dressing capability as it reduces wheel dressing time by nearly 90% when compared to using Stationary Dressers. This has enhanced productivity & performance on all CNC OD Grinders.

This ‘Table Mounted Diamond Roll Assembly with Quick Roll Changeover Feature’ can be retrofitted even on your existing machine where the machine ABC (admit-between-centres) allows for it.

For more details, please email us on [email protected]