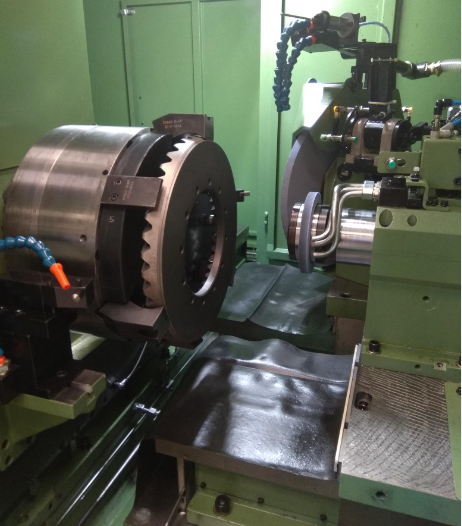

IG 150U SPM

Crown wheel is a crucial component in all commercial vehicles and it is one of the most stress-prone parts of a heavy-vehicle. Volvo Commercial Vehicles Limited (VE Commercial),

a joint venture between the $106 billion Volvo Group worldwide and Eicher motors Ltd., manufactures automotive products across 5 divisions in India.

VE Commercial was facing rejection of Crown Wheels since they were being manufactured by the hard part turning process.

VE Commercial’s Challenge:

- Crown wheels produced had defects such as flatness, inaccurate surface finish and poor tolerance

- Heavy investments of efforts and expenditure incurred in detailed inspection of all the parts produced & rejections were resulting in high cost due to poor quality.

MGT’s Solution:

- MGT accepted the challenge of producing these critical drive-train parts demanding highest-quality, first-time-right from the machine without high inspection costs & rejections.

Hard turning was replaced by MGT’s precision grinding solution to overcome this challenge. - Designers at MGT developed an indigenous CNC Universal grinding machine – IG 150U SPM for bore and face grinding to address the requirements of VE Commercial.

- The Crown Wheels manufactured on MGT’s IG 150U SPM matched VE Commercial’s CTQ requirements of 10-micron flatness on an 80 mm long radial ground face reducing the rejection rate significantly.

Results achieved by IG 150U SPM

| Machine | IG 150U SPM |

|---|---|

| Operation | Bore & Face grinding |

| Stock Removal | 0.3 mm on ID & 0.15mm on face |

| Flatness on front face | 0.01 mm |

| Surface Roughness | 0.6 µm Ra on Face 0.4 µm Ra in Bore |

| Face run out wrt to bore | 0.01 mm |

For customised solutions to niche problems, contact us at [email protected]