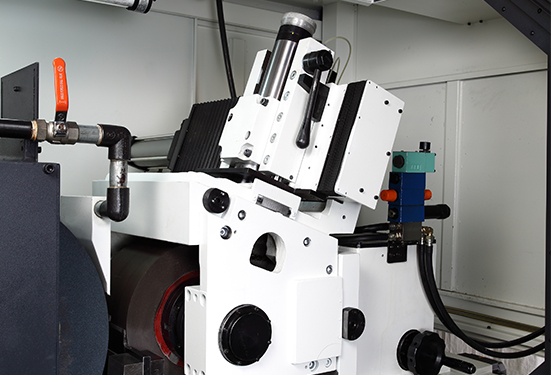

MGT’s VAS team replaced the obsolete CNC system on the Centerless Grinder at customer’s end with minimum of downtime.

CNC system replacement at Customer’s end in 3 days

Challenges:

Customer was facing heavy production losses due to frequent breakdown of the CNC system on their old Centerless Grinding machine. Troubleshooting during maintenance was also posing problems.

Solutions:

The only solution that the situation demanded was the replacement of the CNC System with minimum stopover of the machine to minimise the losses.

Approach:

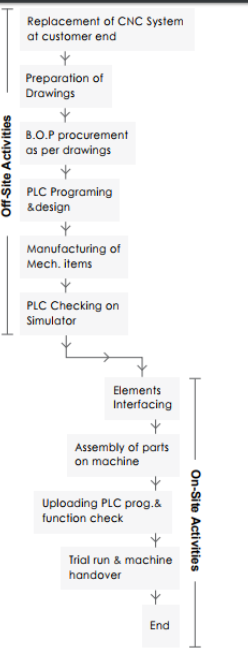

MGT’s Value Added Services-VAS team studied the complete requirement of the customer and prepared a written down procedure for the CNC System replacement, marking all elements as needed-to-be-replaced for the proper function of the machine. Activities were broken down focusing on minimum on-site and maximum off-site actions.

All off-site activities were completed at MGT including Function check for PLC logics as required for the machine. The CNC System, drives, servo motors and other related elements were replaced on the machine at the customer’s site as per the on-site activity schedules.

Result:

The MGT VAS team carried out the entire procedure with utmost coordination. They were able to replace the CNC System in a stipulated time limit of three days & the machine was up for production on the fourth day.